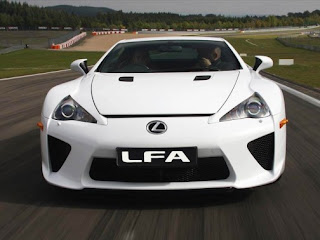

The 2011 Lexus LFA isn't the fastest car ever made, nor the most powerful or even the quickest to 60 MPH. It can't even match the ZR1 around the Nürburgring. So why will this Toyota cost nearly $400,000?

The 2011 Lexus LFA isn't the fastest car ever made, nor the most powerful or even the quickest to 60 MPH. It can't even match the ZR1 around the Nürburgring. So why will this Toyota cost nearly $400,000?Full Disclosure: Lexus wanted us to drive the LFA so badly they flew me to Miami and put me up in a fancy hotel. Also, they fed me cornbread with jalapenos in it. If anyone wants to bribe me, southern food is definitely the way to do it, but I'd really have preferred country ham biscuits and red eye gravy.

View the gallery

View the galleryYou've probably been bewildered by how much attention one car from a previously maligned automaker is getting on this and other enthusiast sites. But the attention we've paid pales in comparison to the attention to technical detail Toyota's displayed in the design and construction of the LFA. The car's gestation has taken nearly a decade not because the program had problems or limited resources, but because Toyota decided to design and build nearly every element of the LFA, its first ever supercar, in-house.

Where most companies Bugatti, Ferrari, Lamborghini and Porsche included — contract out things like gearboxes and the design and construction of carbon fiber components, Lexus chose to teach itself how to make those things better than anyone else, then build its own tools in order to make them.

Where most companies Bugatti, Ferrari, Lamborghini and Porsche included — contract out things like gearboxes and the design and construction of carbon fiber components, Lexus chose to teach itself how to make those things better than anyone else, then build its own tools in order to make them.

Take the carbon fiber, for instance. To make the LFA's, Toyota created one of only two circular looms in the entire world, then used it to simultaneously weave one tube of carbon inside another. They built this system just to make the A-pillars on the car.

Take the carbon fiber, for instance. To make the LFA's, Toyota created one of only two circular looms in the entire world, then used it to simultaneously weave one tube of carbon inside another. They built this system just to make the A-pillars on the car.This all sounded like little more than corporate grandstanding to us. It's the largest car company on earth patting itself on the back for being able to use the money it got selling the automotive equivalent of beige orthopedic shoes to build some fancy tools.

That attitude lasted all the way to turn 6 at the Homestead Speedway road course. An over enthusiastic application of the sharp throttle had the 552 HP, 4.8-liter V10 spinning rapidly towards its 9,500 RPM redline and the tail sliding out towards the grass. Normally that'd have been an oh-shit-I'm-going-to-break-a-$400K-car moment, especially in an unfamiliar supercar, but in the LFA it barely requires conscious correction as it just blended into rocketing down the following straight at three-figure speeds. In fact, oversteer in the LFA doesn't feel so much like oversteer as it does like the rear tires are sitting on castors and being pushed around by a couple of assistants. There's no body roll, no drama, just complete communication and smooth recovery. The reason for that? The impossibly anal approach Toyota took when building the LFA.

The LFA has an unprecedentedly low center of gravity of 17 3/4" — located directly beneath the steering wheel's rim. So far a conventional attribute executed perfectly, but how that CoG got there is way more complicated. First, the engine is located way back in the engine bay and mounts to a 6-speed rear-mounted transaxle through a carbon torque tube. The oil coolers are in the front fenders, while the radiators are at the rear to aid weight distribution, they're fed by the shoulder scoops. That creates a 48% front, 52% rear distribution for the 3263 Lb curb weight. That accounts for the CoG's position front-to-rear, but not vertically. That was achieved by using a world's first counter gear to raise the relative height of the torque tube, allowing the engine to be mounted incredibly low in the car, accounting for the CoG's height.

The LFA has an unprecedentedly low center of gravity of 17 3/4" — located directly beneath the steering wheel's rim. So far a conventional attribute executed perfectly, but how that CoG got there is way more complicated. First, the engine is located way back in the engine bay and mounts to a 6-speed rear-mounted transaxle through a carbon torque tube. The oil coolers are in the front fenders, while the radiators are at the rear to aid weight distribution, they're fed by the shoulder scoops. That creates a 48% front, 52% rear distribution for the 3263 Lb curb weight. That accounts for the CoG's position front-to-rear, but not vertically. That was achieved by using a world's first counter gear to raise the relative height of the torque tube, allowing the engine to be mounted incredibly low in the car, accounting for the CoG's height.Of course, that's still only part of the story. The rigid drivetrain assembly (engine, torque tube, transaxle) is connected to the car by four mounts positioned at the geometric extremes of the unit. With no twist in the assembly due to torque, this arrangement eliminates the effect of power delivery on the chassis, there's no torque reaction.

posted by : http://automotivecarmax.blogspot.com/

No comments:

Post a Comment